Solid oxide fuel cells with a thin film electrolyte: A review on manufacturing technologies and electrochemical characteristics

Abstract

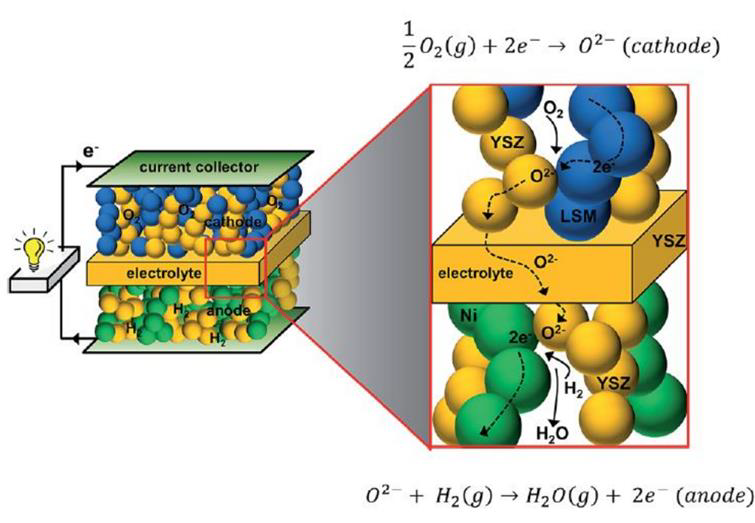

Solid oxide fuel cells (SOFCs) are electrochemical systems converting the energy released during fuel oxidation into electrical energy. SOFCs are considered as a promising clean energy technology due to the high efficiency of fuel-to-power conversion and environmental friendliness. The potential applications of SOFCs extend from stationary power generation units for industrial and household facilities to auxiliary power units in vehicles and portable power sources. One of the main elements of SOFCs is a solid oxide electrolyte possessing ionic conductivity at high temperatures (above 700 °C). The main challenge in the SOFC commercialization is related to their high operating temperature, which entails materials degradation, short life-time, long start-up and shut-down times, and high cost. One of the most effective ways to reduce the SOFC operating temperature is to minimize the electrolyte thickness. In this regard, fabrication of SOFCs with a thin film electrolyte has been attracting high research activity over the past few decades. Different fabrication techniques were reported to be applicable for manufacturing thin film SOFCs, and the fuel cell performance was found to be highly dependent on the appropriate selection of materials and processing technologies. The present review is focused on state-of-the-art fabrication technologies of the thin film SOFCs. A brief survey of configurations and geometries of the thin film SOFCs and methods of deposition of solid-oxide films is given. Special attention is focused on the electrical generation performance of the thin film SOFCs.

Keywords

Full Text:

PDFReferences

Wang SY, Jiang SP, Prospects of fuel cell technologies, National Science Review. 4 (2017) 163–166. https://doi.org/10.1093/nsr/nww099

Trapeznikov AN, Shaikhatdinov FA, Khokhonov AA, Agarkov DA, et al., Obzor kharakteristik toplivnyh elementov izgotavlivaemyh i primenyaemyh na avtomobilnom transporte v Rossii [Overview of characteristics of fuel cells manufactured and applied on motor transport in Russia], Uspekhi v Khimii i Khimicheskoi Tekhnologii, XXXIV. (12) (2020) 43–46.

Jiang SP, Challenges in the development of reversible solid oxide cell technologies: a mini review, Asia Pac. J. Chem. Eng. 11 (2016) 386–391. https://doi.org/10.1002/apj.1987

Stambouli AB, Traversa E, Solid oxide fuel cells (SOFCs): a review of an environmentally clean and efficient source of energy, Renew. Sustain. Energy Rev. 6 (2002) 433–455. https://doi.org/10.1016/S1364-0321(02)00014-X

Brett DJL, Atkinson A, Brandon NP, Skinner SJ, Intermediate temperature solid oxide fuel cells, Chem. Soc. Rev. 37 (2008) 1568–1578. https://doi.org/10.1039/B612060C

Boldrin P, Brandon NP, Progress and outlook for solid oxide fuel cells for transportation applications, Nature Catalysis. 2 (2019) 571–577. https://doi.org/10.1038/s41929-019-0310-y

Singh M, Zappa D, Comini E, Solid oxide fuel cell: Decade of progress, future perspectives and challenges, Int. J. Hydrogen Energy. 46 (2021) 27643–27674. https://doi.org/10.1016/j.ijhydene.2021.06.020

Escudero MJ, Yeste MP, Cauqui MA, Muñoz MA, Performance of a direct methane solid oxide fuel cell using nickel-ceria-yttria stabilized zirconia as the anode, Materials. 13 (2020) 599. https://doi.org/10.3390/ma13030599

Sengodan S, Lan R, Humphreys J, Du D, et al., Advances in reforming and partial oxidation of hydrocarbons for hydrogen production and fuel cell applications, Renewable and Sustainable Energy Reviews. 82 (2018) 761–780. http://dx.doi.org/10.1016/j.rser.2017.09.071

Fischer F, Hauser M, Hauck M, Herrmann S, et al., Effect of internal hydrocarbon reforming during coupled operation of a biomass gasifier with hot gas cleaning and SOFC stacks, Energy Sci Eng. 7 (2019) 1140–1153. https://doi.org/10.1002/ese3.334

van Biert L, Godjevac M, Visser K, Aravind PV, Dynamic modelling of a direct internal reforming solid oxide fuel cell stack based on single cell experiments, Applied Energy. 250 (2019) 976-990. https://doi.org/10.1016/j.apenergy.2019.05.053

Golkhatmi SZ, Asghar MI, Lund PD, A review on solid oxide fuel cell durability: Latest progress, mechanisms, and study tools, Renew. Sustain. Energy Rev. 161 (2022) 112339. https://doi.org/10.1016/j.rser.2022.112339

Mahato N, Banerjee A, Gupta A, Omar S, et al., Progress in material selection for solid oxide fuel cell technology: a review, Prog. Mater. Sci. 72 (2015) 141–337. https://doi.org/10.1016/j.pmatsci.2015.01.001

Zhang J, Ricote S, Hendriksen PV, Chen Y, Advanced materials for thin-film solid oxide fuel cells: recent progress and challenges in boosting the device performance at low temperatures, Adv. Funct. Mater. 32 (2022) 2111205. https://doi.org/10.1002/adfm.202111205

Sun C, Hui R, Roller J, Cathode materials for solid oxide fuel cells: a review, J. Solid State Electrochem. 14 (2010) 1125–1144. https://doi.org/10.1007/s10008-009-0932-0

Vinoth Kumar R, Khandale AP, A review on recent progress and selection of cobalt-based cathode materials for low temperature-solid oxide fuel cells, Renewable and Sustainable Energy Reviews. 156 (2022). https://doi.org/10.1016/j.rser.2021.111985

Zakaria Z, Hassan SHA, Shaari N, Yahaya AZ, et al., A review on recent status and challenges of yttria stabilized zirconia modification to lowering the temperature of solid oxide fuel cells operation, Int. J. Energy Res. 44 (2020) 631–650. https://doi.org/10.1002/er.4944

Bieberle-Hütter A, Beckel D, Infortuna A, Muecke UP, et al., A micro-solid oxide fuel cell system as battery replacement, Journal of Power Sources. 177 (2008) 123–130. https://doi.org/10.1016/j.jpowsour.2007.10.092

Wang HK, Alfred JS, Thangadurai V, Trends in electrode development for next generation solid oxide fuel cells, J. Mater. Chem. A. 4 (2016) 17913–17932. https://doi.org/10.1039/C6TA06757C

Nakamura A, Wagner JB, Defect structure, ionic conductivity, and diffusion in yttria stabilized zirconia and related oxide electrolytes with fluorite structure, J. Electrochem. Soc. 133 (1986) 1542–1545. https://doi.org/10.1149/1.2108965

Ioffe AI, Rutman DS, Karpachov SV, On the nature of the conductivity maximum in zirconia-based solid electrolytes, Electrochimica Acta. 23 (1978) 141–142. https://doi.org/10.1016/0013-4686(78)80110-8

Atkinson A, Barnett S, Gorte RJ, Irvine JTS, et al., Advanced anodes for high-temperature fuel cells, Nat. Mater. 3 (2004) 17–27. https://doi.org/10.1038/nmat1040

da Silva FS, de Souza TM, Novel materials for solid oxide fuel cell technologies: A literature review, Int. J. Hydrogen Energy. 42 (2017) 26020–26036. http://dx.doi.org/10.1016/j.ijhydene.2017.08.105

Kan WH, Thangadurai V, Challenges and prospects of anodes for solid oxide fuel cells (SOFCs), Ionics. 21 (2015) 301–318. https://doi.org/10.1007/s11581-014-1334-6

Liu Y, Shao Z, Mori T, Jiang SP, Development of nickel based cermet anode materials in solid oxide fuel cells – now and future, Materials Reports: Energy. 1 (2021) 100003. https://doi.org/10.1016/j.matre.2020.11.002

Faes A, Hessler-Wyser A, Zryd A, Van herle J, A review of redox cycling of solid oxide fuel cells anode, Membranes. 2 (2012) 585–664. https://doi.org/10.3390/membranes2030585

Tarancon A, Strategies for lowering solid oxide fuel cells operating temperature, Energies. 2 (2009) 1130–1150. https://doi.org/10.3390/en20401130

Ndubuisi A, Abouali S, Singh K, Thangadurai V, Recent advances, practical challenges, and perspectives of intermediate temperature solid oxide fuel cell cathodes, J. Mater. Chem. A. 10 (2022) 2196–2227. https://doi.org/10.1039/d1ta08475e

Katsuki M, Wang S, Dokiya M, Hashimoto T, High temperature properties of La0.6Sr0.4Co0.8Fe0.2O3‑δ: oxygen nonstoichiometry and chemical diffusion constant, Solid State Ionics. 156 (2003) 453–461. https://doi.org/10.1016/S0167-2738(02)00733-6

Lane JA, Benson SJ, Waller D, Kilner JA, Oxygen transport in La0.6Sr0.4Co0.2Fe0.8O3‑δ, Solid State Ionics. 121 (1999) 201–208. https://doi.org/10.1016/S0167-2738(99)00014-4

Ishigaki T, Yamaguchi S, Mizusaki J, Fueki K, Tracer diffusion coefficient of oxide ions in LaCoO3 single crystal, Journal of Solid State Chemistry. 54 (1984) 100–107. https://doi.org/10.1016/0022-4596(84)90136-1

de Souza RA, Kilner JA, Oxygen transport in La-Sr-Mn-Co-O perovskites, Solid State Ionics. 126 (1999) 153–161. https://doi.org/10.1016/S0167-2738(97)00499-2

Jiang SP, Development of lanthanum strontium cobalt ferrite perovskite electrodes of solid oxide fuel cells – A review. Int. J. Hydrogen Energy. 44 (2019) 7448–7493. https://doi.org/10.1016/j.ijhydene.2019.01.212

Boehm E, Bassat JM, Dordor P, Mauvy F, et al., Oxygen diffusion and transport properties in non-stoichiometric Ln2-xNiO4+ oxides, Solid State Ionics. 176 (2005) 2717–2725. https://doi.org/10.1016/J.SSI.2005.06.033

Kilner JA, Shaw CKM, Mass transport in La2Ni1‑xCoxO4+d oxides with the K2NiF4 structure, Solid State Ionics. 154–155 (2002) 523–527. http://dx.doi.org/10.1016/S0167-2738(02)00506-4

Ding P, Li W, Zhao H, Wu C, et al., Review on Ruddlesden–Popper perovskites as cathode for solid oxide fuel cells, J. Phys. Mater. 4 (2021) 022002. https://doi.org/10.1088/2515-7639/abe392

Tang H, Jin Z, Wu Y, Liu W, Bi L, Cobalt-free nanofiber cathodes for proton conducting solid oxide fuel cells, Electrochemistry Communications. 100 (2019) 108–112. https://doi.org/10.1016/j.elecom.2019.01.022

Tarutin AP, Lyagaeva JG, Medvedev DA, Bi L, et al., Recent advances in layered Ln2NiO4+d nickelates: fundamentals and prospects of their applications in protonic ceramic fuel and electrolysis cells, Journal of Materials Chemistry A. 9 (1) (2021) 154–195. http://dx.doi.org/10.1039/d0ta08132a

Hodjati-Pugh O, Dhir A, Steinberger-Wilckens R, The development of current collection in micro-tubular solid oxide fuel cells – a review, Appl. Sci. 11 (2021) 1077. https://doi.org/10.3390/app11031077

Kuterbekov KA, Nikonov AV, Bekmyrza KZ, Pavzderin NB, et al., Classification of solid oxide fuel cells, Nanomaterials. 12 (2022) 1059. https://doi.org/10.3390/nano12071059

Su PC, Chao CC, Shim JH, Fasching R, et al., Solid oxide fuel cell with corrugated thin film electrolyte, Nano Lett. 8 (2008) 2289–2292. https://doi.org/10.1021/nl800977z

Khan MZ, Iltaf A, Ishfaq HA, Khan FN, et al., Flat-tubular solid oxide fuel cells and stacks: a review, Journal of Asian Ceramic Societies. 9 (3) (2021) 745–770. https://doi.org/10.1080/21870764.2021.1920135

Lemański M, Topolski J, Badur J. Analysis strategies for gas turbine – solid oxide fuel cell hybrid cycles. Technical, economic, and environmental aspects of combined cycle power plants. Gdańsk: TU Press; 2004. 213–220.

Powell R, Rossnagel S. PVD for microelectronics: sputter deposition applied to semiconductor manufacturing. Academic Press; 1999. 419 p.

Yang Y, Zhang Y, Yan M, A review on the preparation of thin-film YSZ electrolyte of SOFCs by magnetron sputtering technology, Separation and Purification Technology. 298 (2022) 121627. https://doi.org/10.1016/j.seppur.2022.121627

Snowdon AL, Jiang Z, Steinberger-Wilckens R, Five-layer reverse tape-casting of IT-SOFC, Int. J. Appl. Ceram. Technol. 19 (2022) 289–298. https://doi.org/10.1111/ijac.13911

Pierson HO. Handbook of chemical vapor deposition (CVD): principles, technology and applications. N.J.: Noyes Publications; 1992. 436 p.

Dunyushkina LA. Vvedeniye v metody polucheniya plyonochnykh elektrolitov dlya tvyordooksidnykh toplivnykh elementov [Introduction into deposition methods of film electrolytes for solid oxide fuel cells]. Ekaterinburg: Publishing and Printing Center of Ural Federal University; 2015. 128 p. Russian.

Abegunde OO, Akinlabi ET, Oladijo OP, Akinlabi S, et al., Overview of thin film deposition techniques, AIMS Materials Science, 6 (2) (2019) 174–199. https://doi.org/10.3934/matersci.2019.2.174

Jaeger RC. Film deposition. Introduction to microelectronic fabrication. 2nd ed. Upper Saddle River: Prentice Hall; 2002. 316 p.

Semiconductor Devices: Physics and Technology. Ed.: Sze SM. NY: John Wiley; 1969. 812 p.

Kuzmichev A, Tsybulsky L. Evaporators with induction heating and their applications. Advances in induction and microwave heating of mineral and organic materials. Ed.: Grundas S. InTech; 2011. – 766 p.

Laukaitis G, Dudonis J, Milcius D, Morphology and growth of e-beam deposited YSZ thin films, Vacuum. 81 (2007) 1288–1291. https://doi.org/10.1016/j.vacuum.2007.01.030

Laukaitis G, Dudonis J, Milcius D, Microstructure and surface morphology of YSZ thin films deposited by e-beam technique, Applied Surface Science. 254 (2008) 2980–2987. https://doi.org/10.1016/j.apsusc.2007.10.041

He X, Meng B, Sun Y, Liu B, Li M, Electron beam physical vapor deposition of YSZ electrolyte coatings for SOFCs, Applied Surface Science. 254 (2008) 7159–7164. https://doi.org/10.1016/j.apsusc.2008.05.271

Yang S, Kim K, Choi H, The properties of Co- and Fe-doped GDC for low-temperature processing of solid oxide fuel cell by electron-beam evaporation, Journal of Nanoscience and Nanotechnology. 8 (2013) 5794–5799. https://doi.org/10.1166/jnn.2013.7562

Suh JH, Kim HS, Park CG. Interfacial structure and crystallinity of YSZ thin films grown by ion beam sputtering for MFIS-FRAM. In: IEEE Nanotechnology Materials and Devices Conference Vol. 1; 2006 Oct 22–25; Gyeongju, South Korea. p. 702. https://doi.org/10.1109/NMDC.2006.4388969

Chen YJ, Wei WC. Investigation of YSZ thin films on silicon wafer and NiO/YSZ deposited by ion beam sputtering deposition (IBSD). Key Engineering Materials. 336–338 (2007) 1788–1790. https://doi.org/10.4028/www.scientific.net/kem.336-338.1788

Sønderby S, Nielsen AJ, Christensen BH, Almtoft KP, et al., Reactive magnetron sputtering of uniform yttria-stabilized zirconia coatings in an industrial setup, Surface & Coatings Technology. 206 (2012) 4126–4131. https://doi.org/10.1016/j.surfcoat.2012.04.007

Kuo YL, Lin SE, Wei WCJ, Su YM, Sputter-deposited 20 mol% gadolinia-doped ceria films on 8 mol% yttria-stabilized zirconia tapes for improved electrochemical performance, Thin Solid Films. 618 (2016) 202–206. https://doi.org/10.1016/j.tsf.2016.03.009

Coddeta P, Caillard A, Vulliet J, Richard C, et al., Multistep magnetron sputtering process and in-situ heat treatment to manufacture thick, fully oxidized and well crystallized YSZ films, Surface and Coatings Technology. 349 (2018) 133–143. https://doi.org/10.1016/j.surfcoat.2018.05.065

Bobrenok OF, Predtechenskii MR, Solid oxide fuel cells with film electrolytes prepared by chemical vapor deposition, Russian Journal of Electrochemistry. 46 (7) (2010) 798–804. https://doi.org/10.1134/S102319351007013X

Hou X, Choy K-L, Processing and applications of aerosol-assisted chemical vapor deposition, Chem. Vap. Deposition. 12 (2006) 583–596. https://doi.org/10.1002/cvde.200600033

Perednis D. Thin Film Deposition by Spray Pyrolysis and the Application in Solid Oxide Fuel Cells [Dissertation]. Zurich (Switzerland); 2003. 166 p.

Vervaele M, Roo BD, Deschaume O, Rajala M, et al., Development of a new direct liquid injection system for nanoparticle deposition by chemical vapor deposition using nanoparticle solutions, Review of Scientific Instruments. 87 (2016) 025101. https://doi.org/10.1063/1.4940937

Aleskovskii VB. Stekhiometriya i sintez tverdykh soedinenii [Stoichiometry and synthesis of solid compounds]. Leningrad: Nauka; 1976. 140 p. Russian.

Suntola T. Atomic Layer Epitaxy // In Handbook of Crystal Growth. V. 3. / Edited by Hurle D.T.J. – Amsterdam: Elsevier, 1994. – P. 601–663.

Nishizawa J, Abe H, Kurabayashi T, Molecular layer epitaxy, J. Electrochem. Soc. 132 (1985) 1197. https://doi.org/10.1149/1.2114058

Puurunen RL, Surface chemistry of atomic layer deposition: a case study for the trimethylaluminum/water process, J. Appl. Phys. 97 (2005) 121–301. https://doi.org/10.1063/1.1940727

Schwartz RW, Chemical solution deposition of perovskite thin films, Chem. Mater. 9 (1997) 2325–2340. https://doi.org/10.1021/cm970286f

Oh EO, Whang CM, Hwang HJ, Lee YR, Thin film yttria-stabilized zirconia (YSZ) electrolyte fabricated by a novel chemical solution deposition (CSD) process for solid oxide fuel cells (SOFCs), Journal of Nanoelectronics and Optoelectronics. 7 (5) (2012) 554–558. https://doi.org/10.1166/jno.2012.1377

Gadea C, Hanniet Q, Lesch A, Marani D, Aqueous metal–organic solutions for YSZ thin film inkjet deposition, J. Mater. Chem. C. 5 (2017) 6021–6029. https://doi.org/10.1039/c7tc01879g

Dunyushkina LA, Khaliullina AS, Kuimov VM , Osinkin DA, et al., Influence of modification of chemical solution deposition on morphology and conductivity of CaZr0.9Y0.1O3-δ films, Solid State Ionics. 329 (2019) 1–7. https://doi.org/10.1016/j.ssi.2018.11.015

Zhou J, Zhang L, Liu C, Pu J, et al., Aqueous tape casting technique for the fabrication of Sc0.1Ce0·01Zr0·89O2+Δ ceramic for electrolyte-supported solid oxide fuel cell, Int. J. Hydrogen Energy. 44 (2019) 21110–21114. https://doi.org/10.1016/j.ijhydene.2019.01.265

Goulart C, de Souza D, Critical analysis of aqueous tape casting, sintering, and characterization of planar yttria-stabilized zirconia electrolytes for SOFC, Int. J. Appl. Ceram. Technol. 14 (2017) 413–423. https://doi.org/10.1111/ijac.12638

Agarkova EA, Agarkov DA, Burmistrov IN, Zadorozhnay OY, et al., Three-layered membranes for planar solid oxide fuel cells of the electrolyte-supported design: characteristics and applications, Russian Journal of Electrochemistry. 56 (2) (2020) 132–138. https://doi.org/10.1134/S1023193520020020

Kwon Y, Han Y, Fabrication of electrolyte-supported solid oxide fuel cells using a tape casting process, Journal of the Ceramic Society of Japan. 128 (6) (2020) 310–316. https://doi.org/10.2109/jcersj2.20006

Kim J, Kim J, Yoon KJ, Son JW, et al., Solid oxide fuel cells with zirconia/ceria bilayer electrolytes via roll calendering process, Journal of Alloys and Compounds. 846 (2020) 156318. https://doi.org/10.1016/j.jallcom.2020.156318

Zhang B, Gong J, Wei K, Yuea S, et al., The instructive role of mechanical properties of polyvinyl alcohol film in the process of YSZ tape calendaring, Ceramics International. 46 (2020) 17010–17017. https://doi.org/10.1016/j.ceramint.2020.03.286

Medvedev D, Lyagaeva J, Vdovin G, Beresnev S, et al., A tape calendering method as an effective way for the preparation of proton ceramic fuel cells with enhanced performance, Electrochimica Acta. 210 (2016) 681–688. https://doi.org/10.1016/j.electacta.2016.05.197

Somalu MR, Muchtar A, Daud WRW, Brandon NP, Screen-printing inks for the fabrication of solid oxide fuel cell films: a review, Renewable and Sustainable Energy Reviews. 75 (2017) 426–439. http://dx.doi.org/10.1016/j.rser.2016.11.008

Zhang Y, Huang X, Lu Z, Liu Z, et al., A study of the process parameters for yttria-stabilized zirconia electrolyte films prepared by screen-printing, Journal of Power Sources. 160 (2) (2006) 1065–1073. https://doi.org/10.1016/j.jpowsour.2006.02.074

Onbilgin S, Timurkutluk B, Timurkutluk C, Celik S, Comparison of electrolyte fabrication techniques on the performance of anode supported solid oxide fuel cells, International Journal of Hydrogen Energy. 45 (60) (2020) 35162–35170. https://doi.org/10.1016/j.ijhydene.2020.01.097

Dollen PV, Barnett SA, A study of screen printed yttria‐stabilized zirconia layers for solid oxide fuel cells, Journal of the American Ceramic Society. 88 (12) (2005) 3361–3368. https://doi.org/10.1111/j.1551-2916.2005.00625.x

Ried P, Lorenz C, Bronstrup A, Graule T, et al., Processing of YSZ screen printing pastes and the characterization of the electrolyte layers for anode supported SOFC, Journal of the European Ceramic Society. 28 (2008) 1801–1808. https://doi.org/10.1016/j.jeurceramsoc.2007.11.018

Hołda AK, Vankelecom IFJ, Understanding and guiding the phase inversion process for synthesis of solvent resistant nanofiltration membranes, J. Appl. Polym. Sci. 132 (27) (2015) 42130. https://doi.org/10.1002/app.42130

Li N, Wang L, Wang M, Ban X, et al., Ni-cermet with straight pore paths as cathode for solid oxide electrolysis cell enabling energy-efficient and coking-resistant conversion of CO2, Journal of Power Sources. 518 (2022) 230787. https://doi.org/10.1016/j.jpowsour.2021.230787

Meng X, Yang N, Meng B, Tan X, et al., Microstructure tailoring of the nickel–yttria stabilised zirconia (Ni–YSZ) cermet hollow fibres, Ceramics International. 38 (8) (2012) 6327–6334. https://doi.org/10.1016/j.ceramint.2012.05.002

Ishihara T, Sato K, Takita Y, Electrophoretic deposition of Y2O3-stabilized ZrO2 electrolyte films in solid oxide fuel cells, J. Am. Ceram. Soc. 79 (4) (1996) 913–919. https://doi.org/10.1111/j.1151-2916.1996.tb08525.x

Sarkar P, Huang X, Nicholson PS, Zirconia-alumina functionally-gradiented composites by electrophoretic deposition techniques, J. Am. Ceram. Soc. 76 (4) (1993) 1055–1056. https://doi.org/10.1111/j.1151-2916.1993.tb05335.x

Meepho M, Wattanasiriwech D, Wattanasiriwech S, Aungkavattana P, Preparation of NiO-YSZ substrate for electrophoretic deposition of thin YSZ film, Energy Procedia. 34 (2013) 714–720. https://doi.org/10.1016/j.egypro.2013.06.804

Kalinina E, Pikalova E, Ermakova L, Bogdanovich N, Challenges of formation of thin-film solid electrolyte layers on non-conductive substrates by electrophoretic deposition, Coatings. 11 (2021) 805. https://doi.org/10.3390/coatings11070805

Pikalova EY, Kalinina EG, Electrophoretic deposition in the solid oxide fuel cell technology: fundamentals and recent advances, Renew. Sustain. Energy Rev. 116 (2019) 109440. https://doi.org/10.1016/j.rser.2019.109440

Parhizkara T, Hafeznezami S, Degradation based operational optimization model to improve the productivity of energy systems, case study: solid oxide fuel cell stacks, Energy Conversion and Management. 158 (2018) 81–91. https://doi.org/10.1016/j.enconman.2017.12.045

Leonard K, Ivanova ME, Weber A, Deibert W, et al., Anode supported planar 5 × 5 cm2 SrZr0.5Ce0.4Y0.1O2.95 based solid oxide protonic fuel cells via sequential tape-casting, Solid State Ionics. 379 (2022) 115918. https://doi.org/10.1016/j.ssi.2022.115918

Liu Z, Chen M, Zhou M, Cao D, et al., Multiple effects of iron and nickel additives on the properties of proton conducting yttrium-doped barium cerate-zirconate electrolytes for high-performance solid oxide fuel cells, ACS Appl. Mater. Interfaces. 12 (45) (2020) 50433–50445. https://dx.doi.org/10.1021/acsami.0c14523

Le LQ, Hernandez CH, Rodriguez MH, Zhu L, et al., Proton-conducting ceramic fuel cells: Scale up and stack integration, Journal of Power Sources. 482 (2021) 228868. https://doi.org/10.1016/j.jpowsour.2020.228868

Majhi SM, Behura SK, S. Bhattacharjee S, Singh BP, et al., Anode supported solid oxide fuel cells (SOFC) by electrophoretic deposition, Int. J. Hydrogen Energy. 36 (2011) 14930–14935. https://doi.org/10.1016/j.ijhydene.2011.02.100

Agarkova EA, Burmistrov IN, Agarkov DA, Zadorozhnaya OY, et al., Bilayered anode supports for planar solid oxide fuel cells: fabrication and electrochemical performance, Materials Letters. 283 (2021) 128752, https://doi.org/10.1016/j.matlet.2020.128752

Kang S, Lee J, Cho GY, Kim Y, et al., Scalable fabrication process of thin-film solid oxide fuel cells with an anode functional layer design and a sputtered electrolyte, Int. J. Hydrogen Energy. 45 (2020) 33980–33992. https://doi.org/10.1016/j.ijhydene.2020.09.033

Solovyev AA, Lebedynskiy AM, Shipilova AV, Ionov IV, et al., Scale-up of solid oxide fuel cells with magnetron sputtered electrolyte, Fuel Cells. 17 (3) (2017) 378–382. https://doi.org/10.1002/fuce.201600227

Sochugov NS, Soloviev AA, Shipilova AV, Rotshtein VP, An ion-plasma technique for formation of anode-supported thin electrolyte films for IT-SOFC applications, Int. J. Hydrogen Energy. 36 (9) (2011) 5550–5556. https://dx.doi.org/10.1016/j.ijhydene.2011.01.159

Kim YJ, Le MC, Evaluation of the thermal and structural stability of planar anode-supported solid oxide fuel cells using a 10 x 10 cm2 single-cell test, Int. J. Hydrogen Energy. 44 (2019) 5517–5529. https://doi.org/10.1016/j.ijhydene.2018.08.099

Lin CK, Anam K, Wu SH, Lee RY Simulation of cracking of electrode assembly in planar solid oxide fuel cell, ECS Transactions. 57 (1) (2013) 2597-2606. https://doi.org/10.1149/05701.2597ecst

Zheng J, Xiao L, Wu M, Lang S, et al., Numerical analysis of thermal stress for a stack of planar solid oxide fuel cells. Energies. 15 (2022) 343. https://doi.org/10.3390/en15010343

Kalib NS, Muchtar A, Somalu MR, Ihsan AKAM, et al., Influence of heat transfer on thermal stress development in solid oxide fuel cells: a review, Journal of Advanced Research in Fluid Mechanics and Thermal Sciences. 54 (2) (2019) 175–184.

Suzuki T, Improvement of SOFC performance using a microtubular, anode-supported SOFC, J. Electrochem. Soc. 153 (5) (2006) A925–A928. https://dx.doi.org/10.1149/1.2185284

Alston T, Kendall K, Palin M, Prica M, et al., A 1000-cell SOFC reactor for domestic cogeneration, Journal of Power Sources. 71 (1998) 271–274. https://doi.org/10.1016/S0378-7753(97)02756-0

Du Y, Finnerty C, Jiang J, Thermal stability of portable microtubular SOFCs and stacks, J. Electrochem. Soc. 155 (2008) B972–B977. https://doi.org/10.1149/1.2953590

Monzón H, Laguna-Bercero MA, Highly stable microtubular cells for portable solid oxide fuel cell applications, Electrochimica Acta. 222 (2016) 1622–1627. https://doi.org/10.1016/j.electacta.2016.11.150

Zazhigalov SV, Popov MP, Nemudry AP, et al., Mathematical modeling and experimental studies of microtubular solid oxide fuel cells, Theor. Found. Chem. Eng. 54 (2020) 647–654. https://doi.org/10.1134/S0040579520040284

Min SH, Song RH, Lee JG, Park MG, et al., Fabrication of anode-supported tubular Ba(Zr0.1Ce0.7Y0.2)O3-δ cell for intermediate temperature solid oxide fuel cells, Ceramics International. 40 (2014) 1513–1518. https://doi.org/10.1016/j.ceramint.2013.07.036

Lawlor V, Griesser S, Buchinger G., Olabi AG, et al., Review of the micro-tubular solid oxide fuel cell Part I. Stack design issues and research activities, Journal of Power Sources. 193 (2009) 387–399. https://doi.org/10.1016/j.jpowsour.2009.02.085

Rabuni MF, Li T, Punmeechao P, Li K, Electrode design for direct-methane micro-tubular solid oxide fuel cell (MTSOFC), Journal of Power Sources. 384 (2018) 287–294. https://doi.org/10.1016/j.jpowsour.2018.03.002

Majewski AJ, Dhir A, Application of silver in microtubular solid oxide fuel cells, Materials for Renewable and Sustainable Energy. 7 (2018) 16. https://doi.org/10.1007/s40243-018-0123-y

Villegas CIR, Rendon CLF, Avila‐Paredes HJ, Performance evaluation of microtubular solid oxide fuel cell prototypes at a laboratory scale and identification of needs related to gas sensors, Proceedings. 2 (2018) 106. https://doi.org/10.3390/ecsa‐4‐04910

Milcarek R, Ahn J, Micro-tubular solid oxide fuel cell polarization and impedance variation with thin porous samarium-doped ceria and gadolinium-doped ceria buffer layer thickness, J. Electrochem. En. Conv. Stor. 18 (2) (2021) 021004. https://doi.org/10.1115/1.4047742

Sahu SK, Panthi D, Soliman I, Feng H, et al., Fabrication and performance of micro-tubular solid oxide cells, Energies. 15 (2022) 3536. https://doi.org/10.3390/en15103536

Laguna-Bercero MA, Férriz A, Larrea A, Correas L, et al., Long-term stability studies of anode-supported microtubular solid oxide fuel cells, Fuel Cells. 13 (6) (2013) 1116–1122. https://doi.org/10.1002/fuce.201300063

Yang NT, Tan XY, Ma ZF, Thursfield A, Fabrication and characterization of Ce0.8Sm0.2O1.9 microtubular dual-structured electrolyte membranes for application in solid oxide fuel cell technology, Journal of The American Ceramic Society. 92 (11) (2009) 2544–2550. https://doi.org/10.1111/j.1551-2916.2009.03267.x

Kovalev IV, Sivcev VP, Guskov PD, Popov MP, et al., A new type of microtubular oxygen permeable membranes fabricated by phase inversion with the use of additive manufacturing technologies, Russian Journal of Electrochemistry. 58 (2022) 585–593. https://doi.org/10.1134/S1023193522070096

Popov MP, Bychkov SF & Nemudry AP, Improvement of performance of oxygen-conducting membranes by electric heating, Dokl. Phys. Chem. 478 (2018) 19–22. https://doi.org/10.1134/S0012501618010050

Voloshin BV, Bulina NV, Popov MP, Nemudry AP, Operando x-ray diffraction analysis of a microtubular La0.6Sr0.4Co0.2Fe0.8O3–δ membrane, Russian Journal of Electrochemistry. 58 (2) (2022) 100–104. https://doi.org/10.1134/S1023193522020100

Ito N, Aoyama S, Masui T, Matsumoto S, et al., Electrochemical analysis of hydrogen membrane fuel cells, J. Power Sources. 185 (2008) 922–926. https://doi.org/10.1016/j.jpowsour.2008.08.004

Aoki Y, Kobayashi S, Yamaguchi T, Tsuji E, et al., Electrochemical impedance spectroscopy of high-efficiency hydrogen membrane fuel cells based on sputter-deposited BaCe0.8Y0.2O3−δ thin films, J. Phys. Chem. C. 120 (2016) 15976−15985. https://doi.org/10.1021/acs.jpcc.5b12593

Aoki Y, Yamaguchi T, Kobayashi S, Zhu C, et al., High efficiency hydrogen membrane fuel cells with BaCe0.8Y0.2O3-δ electrolyte thin films and Pd1-xAgx solid anodes, J. Electrochem. Soc. 164 (6) (2017) F577–F581. https://doi.org/10.1149/2.0661706jes

Tucker MC, Progress in metal-supported solid oxide fuel cells: a review, Journal of Power Sources. 195 (2010) 4570–4582. https://doi.org/10.1016/j.jpowsour.2010.02.035

Ruhma Z, Yashiro K, Oikawa I, Takamura H, et al., Metal-supported SOFC fabricated by tape casting and its characterization: a study of the co-sintering process, J. Eng. Technol. Sci. 53 (5) (2021) 210511. https://doi.org/10.5614/j.eng.technol.sci.2021.53.5.11

Zhou Z, Nadimpalli VK, Pedersen DB, Esposito V, Degradation mechanisms of metal-supported solid oxide cells and countermeasures: a review, Materials. 14 (2021) 3139. https://doi.org/10.3390/ma14113139

Roehrens D, Packbier U, Fang Q, Blum L, et al., Operation of thin-film electrolyte metal-supported solid oxide fuel cells in lightweight and stationary stacks: material and microstructural aspects, Materials. 9 (2016) 762. https://doi.org/10.3390/ma9090762

Kim KJ, Kim SJ, Choi GM, Y0.08Sr0.88TiO3–CeO2 composite as a diffusion barrier layer for stainless-steel supported solid oxide fuel cell, J. Power Sources. 307 (2016) 385–390. https://doi.org/10.1016/j.jpowsour.2015.12.130

Uchiyama K, Isse Y, Hori Y, Nishida T, et al., Structural and electrical characterization of Y-doped SrZrO3 thin films for solid oxide fuel cells. In: Proceeding of 6th Thin Film Materials & Devices Meeting; 2009 November 2-3; Kyoto, Japan, 100228102.

Kim KJ, Park BH, Kim SJ, Lee Y, et al., Micro solid oxide fuel cell fabricated on porous stainless steel: a new strategy for enhanced thermal cycling ability, Scientific Reports. 6 (2016) 22443. https://doi.org/10.1038/srep22443

Hwang C, Tsai CH, Lo CH, Sun SH, Plasma sprayed metal supported YSZ/Ni–LSGM–LSCF ITSOFC with nanostructured anode, J. Power Sources. 180 (2008) 132–142. https://doi.org/10.1016/j.jpowsour.2008.01.075

Sumi H, Shimada H, Yamaguchi Y, Yamaguchi T, Metal-supported microtubular solid oxide fuel cells with ceria-based electrolytes, Journal of the Ceramic Society of Japan. 125 (4) (2017) 208-212. https://doi.org/10.2109/jcersj2.16221

Ishihara T, Yan J, Enoki M, Okada S, et al., Ni–Fe Alloy-Supported Intermediate Temperature SOFCs Using LaGaO3LaGaO3 Electrolyte Film for Quick Startup, J. Fuel Cell Sci. Technol. 5 (3) (2008) 031205. https://doi.org/10.1115/1.2930763

Solovyev AA, Rabotkin SV, Shipilova AV, Kirdyashkin AI, et al., Solid oxide fuel cell with Ni-Al support, Int. J. Hydrogen Energy. 40 (2015) 14077–14084. http://dx.doi.org/10.1016/j.ijhydene.2015.07.151

Ju YW, Eto H, Inagaki T, Ishihara T, High power SOFC using LSGM film on NiFe porous bi-metal substrate, ECS Trans. 25 (2) (2009) 719–726. https://doi.org/10.1149/1.3205587

Vasylechko L, Vashook V, Savytskii D, Senyshyn A, et al., Crystal structure, thermal expansion and conductivity of anisotropic La1−xSrxGa1−2xMg2xO3−y (x=0.05, 0.1) single crystals, Journal of Solid State Chemistry. 172 (2) (2003) 396-411. https://doi.org/10.1016/S0022-4596(03)00016-1

Yu J, Liu H, Chen X, Xing J, et al., Ionic conductivity and crystal structure of LSGM with different element mole ratios, Fuel Cells. 21 (2021) 149–154. https://doi.org/10.1002/fuce.202000056

Tucker MC, Kurokawa H, Jacobson CP, De Jonghe LC, et al., A fundamental study of chromium deposition on solid oxide fuel cell cathode materials. 160 (1) (2006) 130–138. https://doi.org/10.1016/j.jpowsour.2006.02.017

Dogdibegovic E, Wang R, Lau GY, Tucker MC, High performance metal-supported solid oxide fuel cells with infiltrated electrodes, Journal of Power Sources. 410–411 (2019) 91–98. https://doi.org/10.1016/j.jpowsour.2018.11.004

Pirou S, Talic B, Brodersen K, Hauch A, et al., Production of a monolithic fuel cell stack with high power density, Nature Communications. 13 (2022) 1263. https://doi.org/10.1038/s41467-022-28970-w

Shim JH, Chao CC, Huang H, Prinz FB, Atomic layer deposition of yttria-stabilized zirconia for solid oxide fuel cells, Chem. Mater. 19 (2007) 3850–3854. https://doi.org/10.1021/cm070913t

Garbayo I, Tarancón A, Santiso J, Cavallaro A, et al., Fabrication and characterization of yttria-stabilized zirconia membranes for micro solid oxide fuel cells. In: Proc. of SPIE - Smart Sensors, Actuators, and MEMS IV; 2009 May 18; Dresden, Germany edited by Ulrich Schmid, Carles Cané, Herbert Shea. V. 7362, 73621B-1. https://doi.org/10.1117/12.821613

Baek JD, Yu CC, Su PC, A silicon-based nanothin film solid oxide fuel cell array with edge reinforced support for enhanced thermal mechanical stability, Nano Lett. 16 (2016) 2413–2417. https://doi.org/10.1021/acs.nanolett.5b05221

Su PC, Chao CC, Shim JH, Fasching R., et al., Solid oxide fuel cell with corrugated thin film electrolyte, Nano Letters. 8 (8) (2008) 2289–2292. https://doi.org/10.1021/nl800977z

Kerman K, Ramanathan S, Performance of solid oxide fuel cells approaching the two-dimensional limit, J. Appl. Phys. 115 (2014) 174307. https://doi.org/10.1063/1.4874738

Huang H, Nakamura M, Su PC, Fasching R, et al., High-performance ultrathin solid oxide fuel cells for low-temperature operation, J. Electrochem. Soc. 154 (2007) B20–B24. https://doi.org/10.1149/1.2372592

Jiang XR, Huang H, Prinz FB, Bent SF, Application of atomic layer deposition of platinum to solid oxide fuel cells, Chem. Mater. 20 (2008) 3897–3905. https://doi.org/10.1021/cm7033189

Evans A, Martynczuk J, Stender D, Schneider CW, et al., Low-temperature micro-solid oxide fuel cells with partially amorphous La0.6Sr0.4CoO3-δ cathodes, Adv. Energy Mater. 5 (2015) 1400747. https://doi.org/10.1002/aenm.201400747

DOI: https://doi.org/10.15826/elmattech.2022.1.006

Copyright (c) 2022 Liliya A. Dunyushkina

This work is licensed under a Creative Commons Attribution 4.0 International License.