Corrosion testing of prospective chrome refractory materials in borosilicate glass melts

Abstract

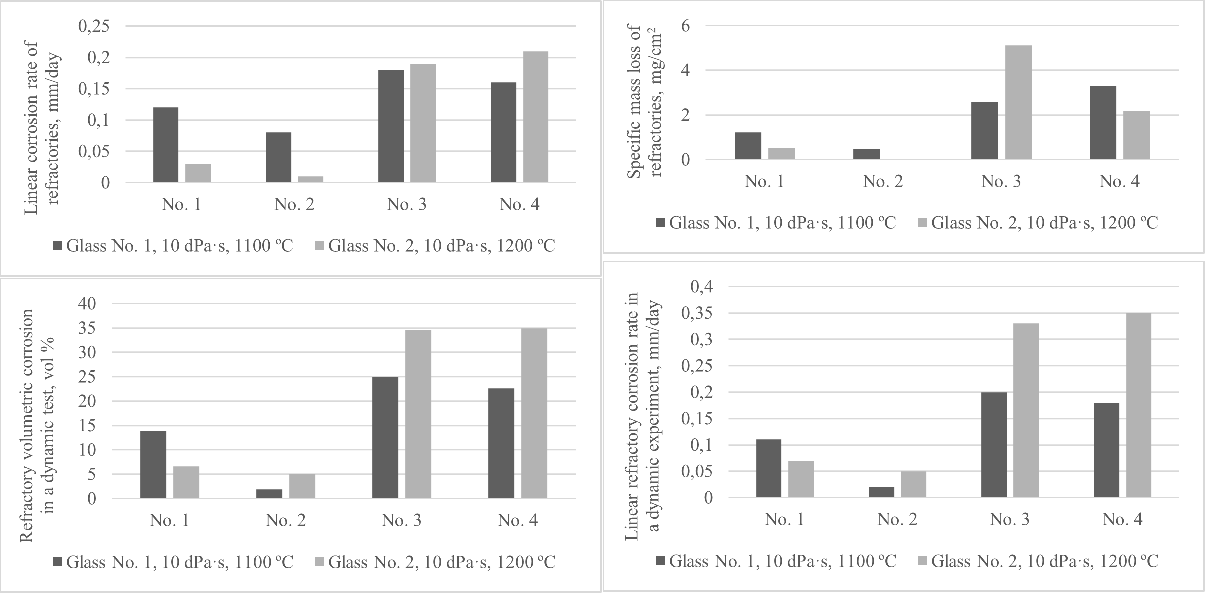

Justification is provided of significant practical relevance of the issue of corrosion and erosion resistance of refractory materials in furnaces with direct electric heating that are used for vitrification of high-level waste. Main promising materials are listed, and an algorithm is given for assessing their resistance to attack of borosilicate glass melts under operating conditions of electric furnaces. Corrosion testing of chrome refractory materials of joint Chinese and Belgian origin has been carried out under static and dynamic conditions in a low-melting borosilicate glass melt and in a borosilicate glass melt containing simulated liquid high-level waste (HLW). A search has been conducted among chrome refractory materials of Chinese and Belgian origin for ones demonstrating the highest glass melt attack resistance with regard to the conditions of HLW solidification. The results of these tests will be considered in the design of removable and small-scale melters when selecting the material for melter lining.

Keywords

Full Text:

PDFReferences

Shaydullin SM, Remizov MB, Kozlov PV, Melent’ev AB, et al., Novyj evakuiruemyj malogabaritnyj plavitel’ s donnym slivom dizayna FGUP PO “Mayak” dlya otverzhdeniya VAO v borosilikatnoe steklo [New removable small-scale melter equipped with a bottom drain system developed at Mayak PA for solidification of HLW in borosilicate glass], Vestnik Natsional’nogo Issledovatel’skogo Yadernogo Universiteta MIFI [Bulletin of the National Research Nuclear University MEPhI], 10(2) (2021) 183–190. Russian. https://doi.org/10.56304/S2304487X21020097

Aloy AS, Trofimenko AV, Koltsova TI, Nikandrova MV, Fiziko-khimicheskie kharakteristiki osteklovannykh model’nykh otkhodov VAO ODTs GKhK [Physical and chemical characteristics of vitrified simulated HLW from the Pilot Demostration Center of the Mining and Chemical Combine], Radioaktivnye otkhody [Radioactive waste], 4(5) (2018) 67–75. Russian.

Tokarev VD, Ignat’ev SS, Popov ON, Analiz sluzhby ogneupornykh materialov v vannykh steklovarennykh pechakh [Analysis of the use of refractory materials in bath-type glass melting furnaces], Steklo i keramika [Glass and ceramics], 5 (2006) 19–22. Russian.

Stanek J. Elektricheskaya varka stekla [Electric melting of glass]. Moscow: Lyogkaya industriya [Light industry]; 1979. 248 p. Translated from Czech.

Pustyl’nikov OM, Guloyan YuA, Usloviya sluzhby i proizvodstva elektroplavlennykh ogneupornykh izdelij [Conditions of use and production of electromelted refractory materials], Steklo i keramika [Glass and ceramics], 21 (2009) 13–17. Russian.

Garaeva NZh, Mazurin AF, Zamyatin SR, Pirumyan GI, et al., Usovershenstvovanie konstruktsii izgotovleniya futerovki blochnogo svoda elektropechi [Improvement of the design and production technology of lining for the block crown of electric furnace] [Extended abstract for a research work]. Sverdlovsk (Russia): [East Research and Design Institute of Refractory Industry]; 1991. 12 p. Russian.

Roth G, Weisenburger S, Vitrification of high-level liquid waste: glass chemistry, process chemistry and 30 process technology, Nuclear Engineering and Design, 202(2) (2000) 197–207. https://doi.org/10.1016/S0029-5493(00)00358-7

GOST 2642.2-86. Methods for the determination of losses of the mass while heating. Moscow, Gosstandart of the USSR Publ., 1986. 8 p. Russian.

Popov SA. Korroziya i sluzhba ogneupornykh materialov v vannykh steklovarennykh pechakh pri vysokotemperaturnoj varke stekla [Corrosion and use of refractory materials in bath-type furnaces during high-temperature glass melting] [Review] Moscow (Russia) [VNIIESM]; 1974. Russian.

Remizov MB, Kazadaev AA, Kozlov PV, Gasparyan MD, et al., Korrozionnye ispytaniya plavlenolitykh ogneupornykh materialov v rasplavakh alumofosfatnykh styokol [Corrosion testing of molten-cast refractory materials in aluminophosphate glass melts], Ogneupory i tekhnicheskaya keramika [Refractories and technical ceramics], 6 (2015) 3–8. Russian.

Remizov MB, Kazadaev AA, Kozlov PV, Gasparyan MD, et al., Issledovanie korrozionnoj ustojchivosti baddeleito korundovykh i chromalumotsirkonovykh ogneupornykh materialov otechestvennogo i importnogo proizvodstva v rasplavakh alumoborfosfatnykh styokol [Study of corrosion resistance of baddeleyite-corundum and chromium-aluminium-zirconium refractory materials manufactured domestically and abroad in aluminium-boron-phosphate glass melts], Ogneupory i tekhnicheskaya keramika [Refractories and technical ceramics], 4–5 (2016) 3–7. Russian.

Shaydullin SM, Remizov MB, Kozlov PV, Dubkov SA, et al., Korrozionnye ispytaniya baddeleitokorundovykh i khromsoderzhashchikh materialov otechestvennogo proizvodstva v rasplavakh borosilikatnykh styokol [Corrosion testing of baddeleyite-corundum and chrome-bearing materials of domestic production in borosilicate glass melts], Novye ogneupory [New refractories], 11 (2022) 3–8. Russian.

Matveeva IV, Slinkin AA. Geterogennyj kataliz v organicheskoj khimii: Bibliograficheskij ukazatel’ otechestvennoj i zarubezhnoj literatury (1958–1960) [Heterogeneous catalysis in organic chemistry: Bibliography index to Russian and Foreign Literary Sources (1958–1960)]. Moscow: Izdatel’stvo Akademii nauk SSSR [Publishing House of the USSR Academy of Sciences]; 1962. 275 p. Russian.

Remizov MB, Kozlov PV, Logunov MB, Koltyshev VK, et al., Kontseptual’nye i tekhnicheskie resheniya po sozdaniyu na “PO “Mayak” ustanovok osteklovyvaniya tekushchikh i nakoplennykh zhidkikh VAO [Conceptual and technical solutions related to creation of facilities for vitrification of current and accumulated liquid HLW at Mayak], Voprosy radiatsionnoj bezopasnosti [Radiation safety problems], 3 (2014) 17–25. Russian.

DOI: https://doi.org/10.15826/elmattech.2024.3.031

Copyright (c) 2024 Sergey M. Shaydullin, Pavel V. Kozlov, Mikhail B. Remizov, Sergey A. Lukin

This work is licensed under a Creative Commons Attribution 4.0 International License.