Field-assisted sintering of refractory oxygen-ion and proton conducting ceramics

Abstract

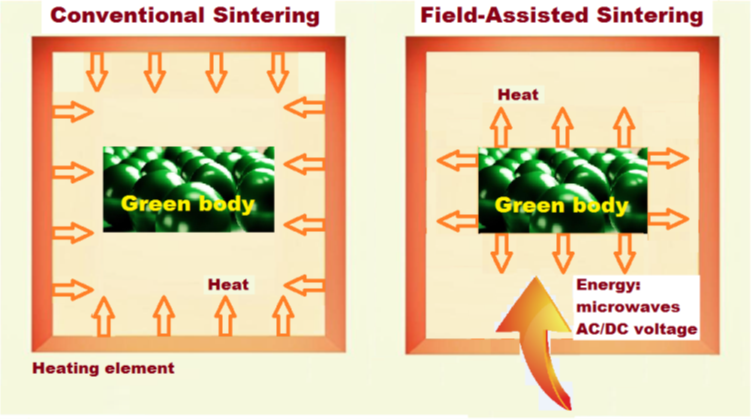

Solid oxides with high oxygen-ion and proton conductivity have been extensively studied for applications in electrochemical devices such as fuel cells, electrolyzers, sensors, hydrogen separators, etc. However, the preparation of high-density ceramic electrolytes is often complicated by the exceptional refractoriness of most oxygen-ion conducting solid oxide phases. Therefore, conventional sintering of these materials is very energy consuming and low effective. In recent years, non-conventional field-assisted sintering technologies (FASTs) such as spark plasma sintering, flash sintering and microwave sintering, have been developed and applied for sintering dense ceramic electrolytes at reduced temperatures. In this article, the applications of FASTs for densification of refractory oxygen-ion and proton conducting ceramics are reviewed, while the mechanisms, advantages and limitations of these technologies are discussed, with special emphasis on the effects of FASTs on the microstructural and transport properties of sintered materials, and the performance of FAST-processed electrochemical cells.

Keywords

Full Text:

PDFReferences

He S, Zou Y, Chen K, Jiang SP, A critical review of key materials and issues in solid oxide cells, Interdisciplinary Materials, 2(1) (2023) 111–136. https://doi.org/10.1002/idm2.12068

Wolf SE, Winterhalder FE, Vibhu V, de Haart LGJ (Bert), et al., Solid oxide electrolysis cells – current material development and industrial application, J. Mater. Chem. A, 11 (2023) 17977–18028. https://doi.org/10.1039/D3TA02161K

Etsell TH, Flengas SN, Electrical properties of solid oxide electrolytes, Chem. Rev., 70(3) (1970) 339–376. https://doi.org/10.1021/cr60265a003

Kreuer KD, Proton-conducting oxides, Annu. Rev. Mater. Res., 33 (2003) 333–359. https://doi.org/10.1146/annurev.matsci.33.022802.091825

Hossain S, Abdalla AM, Jamain SNB, Zaini JH, et al., A review on proton conducting electrolytes for clean energy and intermediate temperature-solid oxide fuel cells, Renew. Sustain. Energy Rev., 79 (2017) 750–764. https://doi.org/10.1016/j.rser.2017.05.147

Duan C, Huang J, Sullivan N, O’Hayre R, Proton-conducting oxides for energy conversion and storage, Appl. Phys. Rev., 7 (2020) 011314. https://doi.org/10.1063/1.5135319

Choi S, Davenport TC, Haile SM, Protonic ceramic electrochemical cells for hydrogen production and electricity generation: exceptional reversibility, stability, and demonstrated faradaic efficiency, Energy Environ. Sci., 12 (2019) 206–215. https://doi.org/10.1039/C8EE02865F

Yatoo MA, Habib F, Malik AH, Qazi MJ, et al., Solid-oxide fuel cells: A critical review of materials for cell components, MRS Communications, 13 (2023) 378–384. https://doi.org/10.1557/s43579-023-00371-0

Yin S, Li M, Zeng Y, Li C, et al., Study of Sm0.2Ce0.8O1.9 (SDC) electrolyte prepared by a simple modified solid-state method, Journal of Rare Earths, 32(8) (2014) 767–771. https://doi.org/10.1016/S1002-0721(14)60138-1

Chourashiya MG, Patil JY, Pawar SH, Jadhav LD, Studies on structural, morphological and electrical properties of Ce1−xGdxO2−(x/2), Materials Chemistry and Physics, 109(1) (2008) 39–44. https://doi.org/10.1016/j.matchemphys.2007.10.028

Matsui K, Yoshida H, Ikuhara Y, Grain-boundary structure and microstructure development mechanism in 2–8 mol % yttria-stabilized zirconia polycrystals, Acta Materialia, 56(6) (2008) 1315–1325. https://doi.org/10.1016/j.actamat.2007.11.026

Kim B-N, Suzuki TS, Morita K, Yoshida H, et al., Densification kinetics during isothermal sintering of 8YSZ, J. Eur. Ceram. Soc., 36(5) (2016) 1269–1275. https://doi.org/10.1016/j.jeurceramsoc.2015.11.041

Han M, Tang X, Peng S, Research on sintering process of YSZ electrolyte, Rare Metals, 25(6) (2006) 209–212. https://doi.org/10.1016/S1001-0521(08)60083-2

Azad A, Subramaniam S, Dung TW, On the development of high density barium metazirconate (BaZrO3) ceramics, J. Alloys Compd., 334 (2002) 118–30. https://doi.org/10.1016/S0925-8388(01)01785-6

Yamazaki Y, Hernandez-Sanchez R, Haile SM, High total proton conductivity in large-grained yttrium-doped barium zirconate, Chem. Mater., 21 (2009) 2755–2762. https://doi.org/10.1021/cm900208w

Gorelov VP, Balakireva VB, Kleshchev YN, et al., Preparation and electrical conductivity of BaZr1–xRxO3–a (R = Sc, Y, Ho, Dy, Gd, In), Inorg. Mater., 37(5) (2001) 535–538. https://doi.org/10.1023/A:1017553506634

Han D, Hatada N, Uda T, Microstructure, proton concentration and proton conductivity of barium zirconate doped with Ho, Er, Tm and Yb, J. Electrochem. Soc., 163(6) (2016) F470–F476. https://doi.org/10.1149/2.0551606jes

Park GS, Mo SI, Kim JH, et al., Characteristics of Li2CO3 as sintering aid for Ce0.8Sm0.2O2−δ electrolyte in solid oxide fuel cells, Korean J. Chem. Eng., 39 (2022) 1796–1804. https://doi.org/10.1007/s11814-022-1112-5

Mirzaei A, Afzali M, Khachatourian AM, Golmohammad M, Enhancing sintering behavior and conductivity of YSZ electrolyte by co-doping of ZnO and MnO2, Materials Chemistry and Physics, 315 (2024) 129051. https://doi.org/10.1016/j.matchemphys.2024.129051

Babilo P, Haile SM, Enhanced sintering of yttrium-doped barium zirconate by addition of ZnO, J. Am. Ceram. Soc., 88(9) (2005) 2362–2368. https://doi.org/10.1111/j.1551-2916.2005.00449.x

Qiao Z, Li S, Li Y, Wu Q, et al., Sintering behavior and physical properties of ZnO-modified BaZrO3 ceramics, Int. J. Appl. Ceram. Technol., 21 (2024) 124–132. https://doi.org/10.1111/ijac.14500

Huang Y, Merkle R, Maier J, Effects of NiO addition on sintering and proton uptake of Ba(Zr,Ce,Y)O3-δ, J. Mater. Chem. A, 9 (2021) 14775. https://doi.org/10.1039/D1TA02555D

Han D, Uemura S, Hiraiwa C, Majima M, et al., Detrimental effect of sintering additives on conducting ceramics: yttrium-doped barium zirconate, ChemSusChem, 11 (2018) 4102–4113. https://doi.org/10.1002/cssc.201801837

Porfirio TC, Muccillo ENS, Muccillo R, Electric field-assisted synthesis/sintering cerium oxide: 5 wt. % gadolinium oxide, J. Eur. Ceram. Soc., 41(14) (2021) 7105–7110, https://doi.org/10.1016/j.jeurceramsoc.2021.07.027

Xu J, Liu Z, Xie Z, He S, et al., DC electric field-assisted hot pressing of zirconia: Methodology, phenomenology, and sintering mechanism, J. Am. Ceram. Soc., 104 (2021) 5571–5583. https://doi.org/10.1111/jace.17963

Guillon O, Gonzalez-Julian J, Dargatz B, Kessel T, et al., Field-assisted sintering technology/spark plasma sintering: mechanisms, materials, and technology developments, Adv. Eng. Mater., 16 (2014) 830–849. https://doi.org/10.1002/adem.201300409

Manière C, Harnois C, Riquet G, Lecourt J, et al., Flash spark plasma sintering of zirconia nanoparticles: Electro-thermal-mechanical-microstructural simulation and scalability solutions. J. Eur. Ceram. Soc., 42(1) 2022 216–226. https://doi.org/10.1016/j.jeurceramsoc.2021.09.021

Raj R, Joule heating during flash-sintering, J. Eur. Ceram. Soc., 32 (2012) 2293–2301. https://doi.org/10.1016/j.jeurceramsoc.2012.02.030

Raj R, Cologna M, Francis JSC, Influence of externally imposed and internally generated electrical fields on grain growth, diffusional creep, sintering and related phenomena in ceramics, J. Am. Ceram. Soc., 94 (2011) 1941–65. https://doi.org/10.1111/j.1551-2916.2011.04652.x

Naik K, Sglavo VM, Raj R, Flash sintering as a nucleation phenomenon and a model thereof, J. Eur. Ceram. Soc., 34 (2014) 4063–4067. https://doi.org/10.1016/j.jeurceramsoc.2014.04.043

Wu J, Wu X, Gao Y, Yan Z, Innovations in electric current-assisted sintering for SOFC: a review of advances in flash sintering and ultrafast high-temperature sintering, Appl. Sci., 14 (2024) 3953. https://doi.org/10.3390/app14103953

Aman B, Acharya S, Reeja-Jayan B, Making the case for scaling up microwave sintering of ceramics, Adv. Eng. Mater., 26 (2024) 2302065. https://doi.org/10.1002/adem.202302065

Agrawal DK, Microwave processing of ceramics: a review, Current Opinion in Solid State & Mat. Sci., 3(5) (1998) 480–486. https://doi.org/10.1016/S1359-0286(98)80011-9

Binner JGP, Vaidhyanathan B. Microwave sintering of ceramics: what does it offer? Key Eng. Mat., 264–268 (2004) 725–730. https://doi.org/10.4028/www.scientific.net/KEM.264-268.725

Fu M, Lin X, Li X, Tao Z, Applications of microwave technology in the field of solid oxide fuel cell – a review, Russ. Chem. Rev., 92(9) (2023) RCR5092. https://doi.org/10.59761/RCR5092

Agrawal D. Microwave sintering of ceramics, composites and metal powders, Editor(s): Zhigang Zak Fang, In Woodhead Publishing Series in Metals and Surface Engineering, Sintering of Advanced Materials, Woodhead Publishing, 2010, Pages 222–248, ISBN 9781845695620

Oghbaei M, Mirzaee O, Microwave versus conventional sintering: a review of fundamentals, advantages and applications, J. Alloys Compd., 494(1–2) (2010) 175–189. https://doi.org/10.1016/j.jallcom.2010.01.068

Chiu WT, Chen CL, Chen YY, A strategy to optimize the thermoelectric performance in a spark plasma sintering process, Sci. Rep., 6 (2016) 23143. https://doi.org/10.1038/srep23143

Prette ALG, Cologna M, Sglavo V, Raj R, Flash-sintering of Co2MnO4 spinel for solid oxide fuel cell applications, J. Power Sources, 196 (2011) 2061–2065. https://doi.org/10.1016/j.jpowsour.2010.10.036

Jiang T, Liu Y, Wang Z, Sun W, et al., An improved direct current sintering technique for proton conductor - BaZr0.1Ce0.7Y0.1Yb0.1O3: the effect of direct current on sintering process, J. Power Sources, 248 (2014) 70–76. http://dx.doi.org/10.1016/j.jpowsour.2013.09.042

Soleimany M, Paydar MH, Wang S, Enhancing the flash-sinterability of BaZr0.1Ce0.7Y0.2O3-d proton-conducting electrolyte by nickel oxide doping for possible application in SOFCs, Int. J. Hydrogen En., 46(19) (2021) 11115–11126. https://doi.org/10.1016/j.ijhydene.2020.06.112

Han M, Tang X, Yin H, Peng S, Fabrication, microstructure and properties of a YSZ electrolyte for SOFCs, J. Power Sources, 16(2) (2007) 757–763. https://doi.org/10.1016/j.jpowsour.2006.11.054

Wang S, Liu Y, He J, Chen F, et al., Spark-plasma-sintered barium zirconate based proton conductors for solid oxide fuel cell and hydrogen separation applications, Int. J. Hydrogen Energy, 40 (2015) 5707–5714. https://doi.org/10.1016/j.ijhydene.2015.02.116

Saini DS, Ghosh A, Tripathy S, Sharma SK, et al., Improved conductivity of spark plasma sintered Ho-substituted BaZrO3 electrolyte ceramics for IT-SOFCs, ACS Appl. Energy Mater., 1 (2018) 3469−3478. https://doi.org/10.1021/acsaem.8b00655

Ahmed I, Kinyanjui FG, Steegstra P, Shen ZJ, et al., Improved proton conductivity in spark-plasma sintered dense ceramic BaZr0.5In0.5O3-δ, Electrochemical and Solid-State Letters, 13(11) (2010) B130–B134. https://doi.org/10.1149/1.3482016

Xu X, Bi L, Zhao XS, Highly-conductive proton-conducting electrolyte membranes with a low sintering temperature for solid oxide fuel cells, J. Membr. Sci., 558 (2018) 17–25. https://doi.org/10.1016/j.memsci.2018.04.037

Wang B, Bi L, Zhao XS, Fabrication of one-step co-fired proton-conducting solid oxide fuel cells with the assistance of microwave sintering, J. Eur. Ceram. Soc., 38(16) (2018) 5620–5624. https://doi.org/10.1016/j.jeurceramsoc.2018.08.020

Khoshghadam-Pireyousefan M, Mohammadzadeh A, Heidarzadeh A, Brabazon D, Fundamentals of spark plasma sintering for metallic, ceramic, and polymer matrix composites production, Editor(s): Dermot Brabazon, Encyclopedia of Materials: Composites, Elsevier, 2021, Pages 822–836, ISBN 9780128197318. https://doi.org/10.1016/B978-0-12-803581-8.11907-1

Tokita M. Spark Plasma Sintering (SPS) method, systems, and applications, in Handbook of Advanced Ceramics, 2nd Ed. (2013), Chapter 11.2.3, 1149–1177.

Bram M, Laptev AM, Mishra TP, Nur K, et al., Application of Electric Current-Assisted Sintering Techniques for the Processing of Advanced Materials, Adv. Eng. Mater., 22 (2020) 2000051. https://doi.org/10.1002/adem.202000051

Supriya S, Electric field assisted spark plasma sintering of ABO3 perovskites: Crystal structure, dielectric behavior and future challenges, Open Ceramics, 18 (2024) 100608. https://doi.org/10.1016/j.oceram.2024.100608

Harrison RW, Morgan J, Buckley J, Bostanchi S, et al., Development and comparison of field assisted sintering techniques to densify CeO2 ceramics, J. Eur. Ceram. Soc., 42(14) (2022) 6599–6607. https://doi.org/10.1016/j.jeurceramsoc.2022.06.079

Kandi H, Koona R, Raju GMJ, Synthesis of SrHfO3 co-doped with Gd2O3 and Yb2O3 for thermal barrier coating applications, Materials Today: Proceedings, 47(9) (2021) 1904–1907. https://doi.org/10.1016/j.matpr.2021.03.66

Saheb N, Hayat U, Hassan SF, Recent advances and future prospects in Spark Plasma Sintered alumina hybrid nanocomposites, Nanomaterials, 9(11) (2019) 1607. https://doi.org/10.3390/nano9111607

Alvarez-Clemares I, Mata-Osoro G, Fernández A, Lopez-Esteban S, et al., Transparent alumina/ceria nanocomposites by spark plasma sintering, Advanced Engineering Materials, 12(11) (2010) 1154–1160. https://doi.org/10.1002/adem.201000176

Yang W, Wang L, Lia Y, Zhou H, et al., An easily sintered, chemically stable indium and tin co-doped barium hafnate electrolyte for hydrogen separation, J. Alloy. Compd., 868 (2021) 159117. https://doi.org/10.1016/j.jallcom.2021.159117

Belyakov SA, Lesnichyova AS, Balakireva VB, Tarutin AP, et al., ZnO sintering additive without negative impact on proton-conducting SrHf0.8Sc0.2O3-δ electrolyte, Ceram. Int. Article in press, https://doi.org/10.1016/j.ceramint.2024.04.331

Gorelov VP, Balakireva VB, Kleshchev YN, Brusentsov VP, Preparation and electrical conductivity of BaZr1–xRxO3–a (R = Sc, Y, Ho, Dy, Gd, In), Inorg. Mater., 37(5) (2001) 535–538. https://doi.org/10.1023/A:1017553506634

Yamazaki Y, Hernandez-Sanchez R, Haile SM, High total proton conductivity in large-grained yttrium-doped barium zirconate, Chem. Mater., 21 (2009) 2755–2762. https://doi.org/10.1021/cm900208w

Han D, Hatada N, Uda T, Microstructure, proton concentration and proton conductivity of barium zirconate doped with Ho, Er, Tm and Yb, J. Electrochem. Soc., 163(6) (2016) F470–F476. https://doi.org/10.1149/2.0551606jes

Gonçalves MD, Maram PS, Navrotsky A, Muccillo R, Effect of synthesis atmosphere on the proton conductivity of Y-doped barium zirconate solid electrolytes, Ceram. Int., 42 (2016) 13689–13696. https://www.elsevier.com/open-access/userlicense/1.0/

Huang Y, Merkle R, Maier J, Effects of NiO addition on sintering and proton uptake of Ba(Zr,Ce,Y)O3-δ, J. Mater. Chem. A, 9 (2021) 14775. https://doi.org/10.1039/D1TA02555D

Han D, Uemura S, Hiraiwa C, Majima M, et al., Detrimental effect of sintering additives on conducting ceramics: yttrium-doped barium zirconate, ChemSusChem, 11 (2018) 4102–4113. https://doi.org/10.1002/cssc.201801837

Han D, Goto K, Hiraiwa C, Majima M, et al., Proton conductive BaZr0.8-xCexY0.2O3-δ: influence of NiO sintering additive on crystal structure, hydration behavior, and conduction properties, ChemSusChem, 14 (2021) 614–623. https://doi.org/10.1002/cssc.202002369

Shakel Z, Loureiro FJA, Antunes I, Mikhalev SM, et al., Tailoring the properties of dense yttrium-doped barium zirconate ceramics with nickel oxide additives by manipulation of the sintering profile, Int. J. Energy Res., 46(15) (2022) 21989–22000. https://doi.org/10.1002/er.8389

Yang W, Liu Y, Wang L, Zhou H, et al., Investigation on properties of BaZr0.6Hf0.2Y0.2O3-δ with sintering aids (ZnO, NiO, Li2O) and its application for hydrogen permeation, Int. J. Hydrogen Energy, 47(86) (2022) 36566–36581. https://doi.org/10.1016/j.ijhydene.2022.08.227

Huang Y, Merkle R, Zhou D, Sigle W, et al., Effect of Ni on electrical properties of Ba(Zr,Ce,Y)O3-δ as electrolyte for protonic ceramic fuel cells, Solid State Ion., 390 (2023) 116113. https://doi.org/10.1016/j.ssi.2022.116113

Trivino-Pelaez A, Perez-Coll D, Aparicio M, Fagg DP, et al., Processing and characterisation of BaZr0.8Y0.2O3-δ proton conductor densified at 1200 °C, J. Mater. Chem. A, 10 (2022) 4428–4439. https://doi.org/10.1039/D1TA09998A

Hocquet S, Dupont V, Cambier F, Ludewig F, et al., Densification of complex shape ceramics parts by SPS, J. Eur. Ceram. Soc., 40(7) (2020) 2586–2596. https://doi.org/10.1016/j.jeurceramsoc.2019.10.038

Paygin V, Dvilis E, Stepanov S, Khasanov O, et al., Manufacturing optically transparent thick zirconia ceramics by spark plasma sintering with the use of collector pressing, Appl. Sci., 11 (2021) 1304. https://doi.org/10.3390/app11031304

Dvilis ES, Khasanov OL, Sokolov VM, Pokholkov JP, Method for compacting powder materials into articles and a mold for implementing the method. U.S. Patent No. 6,919,041, 19 July 2005. Russian Patent #2225280 (10.03.2004); Europatent No 1459823 (11.03.2009).

Cologna M, Rashkova B, Raj R, Flash sintering of nanograin zirconia in <5 s at 850°C, J. Am. Ceram. Soc., 93 (2010) 3556–3559. https://doi.org/10.1111/j.1551-2916.2010.04089.x

Bu J, Jonsson PG, Zhao Z, Dense and translucent BaZrxCe0.8-xY0.2O3-δ (x=0.5, 0.6, 0.7) proton conductors prepared by spark plasma sintering, Scr. Mater., 107 (2015) 145–148. https://doi.org/10.1016/j.scriptamat.2015.06.006

Maekawa T, Kurosaki K, Yamanaka S, Thermal and mechanical properties of perovskite-type barium hafnate, J. Alloys Compd., 407(1–2) (2006) 44–48. https://doi.org/10.1016/j.jallcom.2005.06.030

Anselmi-Tamburini U, Buscaglia MT, Viviani M, Bassoli M, et al., Solid-state synthesis and spark plasma sintering of submicron BaYxZr1-xO3-x/2 (x = 0, 0.08 and 0.16) ceramics, J. Eur. Ceram. Soc., 26 (2006) 2313–2318. https://doi.org/10.1016/j.jeurceramsoc.2005.04.022

Ricote S, Caboche G, Estournes C, Bonanos N, Synthesis, sintering, and electrical properties of BaCe0.9-xZrxY0.1O3-δ, Journal of Nanomaterials, 2008 (2008) 354258. https://doi.org/10.1155/2008/354258

Park HJ, Munir ZA, Kim ST, Grain boundary protonic conductivity in highly dense nano-crystalline Y-doped BaZrO3, J. Korean Chem. Soc., 47 (2010) 70–71. https://doi.org/10.4191/KCERS.2010.47.1.071

Park HJ, Roh JW, Protonic conduction of nanostructured Y-doped BaZrO3, Journal of Nanomaterials, (2016) 8757305. https://doi.org/10.1155/2016/8757305

Wallis J, Urban L, Grimmer C, Bodnar W, Structural and electrical properties of BaZr0.7Ce0.2Y0.1O3–d proton conducting ceramic fabricated by spark plasma sintering, Solid State Ionics, 345 (2020) 115118. https://doi.org/10.1016/j.ssi.2019.115118

Simonenko TL, Kalinina MV, Simonenko NP, Simonenko EP, et al., Synthesis of BaCe0.9–xZrxY0.1O3–δ nanopowders and the study of proton conductors fabricated on their basis by low-temperature spark plasma sintering, Int. J. Hydrogen En., 44(36) (2019) 20345–20354. https://doi.org/10.1016/j.ijhydene.2019.05.231

Wang D, Zhang Z, Song T, Sun H, et al., Synthesis of BaZr0.1Ce0.7Y0.2O3-δ nano-powders by aqueous gel-casting for proton-conducting solid oxide fuel cells, Int. J. Appl. Ceram., Technol. 21 (2024) 299–310. https://doi.org/10.1111/ijac.14497

Kindelmann M, Escolastico S, Almar L, Vayyala A, et al., Highly conductive grain boundaries in cold-sintered barium zirconate-based proton conductors, J. Mater. Chem. A, 12 (2024) 3977–3988. https://doi.org/10.1039/D3TA07076J

Todd RI, Zapata-Solvas E, Bonilla RS, Sneddon T, et al., Electrical characteristics of flash sintering: thermal runaway of Joule heating, J. Eur. Ceram. Soc., 35(6) (2015) 1865–1877. https://doi.org/10.1016/j.jeurceramsoc.2014.12.022

Caliman LB, Bichaud E, Soudant P, Gouvea D, et al., A simple flash sintering setup under applied mechanical stress and controlled atmosphere, MethodsX, 2 (2015) 392–398. http://dx.doi.org/10.1016/j.mex.2015.10.004

Yoon B, Avila V, Lavagnini IR, Campos JV, et al., Reactive Flash Sintering of Ceramics: A Review, Adv. Eng. Mater., 25 (2023) 2200731. https://doi.org/10.1002/adem.202200731

Ren K, Liu J, Wang Y, Flash sintering of yttria-stabilized zirconia: Fundamental understanding and applications, Scripta Materialia, 187 (2020) 371–378. https://doi.org/10.1016/j.scriptamat.2020.06.040

Steil MC, Marinha D, Aman Y, Gomes JRC, et al., From conventional ac flash-sintering of YSZ to hyper-flash and double flash, J. Eur. Ceram. Soc. 33 (2013) 2093–2101. http://dx.doi.org/10.1016/j.jeurceramsoc.2013.03.019

Francis JSC, Raj R, Influence of the field and the current limit on flash sintering at isothermal furnace temperatures, J. Am. Ceram. Soc., 96(9) (2013) 2754–2758. https://doi.org/10.1111/jace.12472

Du Y, Stevenson AJ, Vernat D, Diaz M, et al., Estimating Joule heating and ionic conductivity during flash sintering of 8YSZ, J. Eur. Ceram. Soc., 36 (2016) 749–759. http://dx.doi.org/10.1016/j.jeurceramsoc.2015.10.037

Bai Y, Zhang Y, Tian Z, Zhang J, et al., Effect of current density on the microstructure and mechanical properties of 3YSZ/Al2O3 composites by flash sintering, Materials, 15(9) (2022) 3110. https://doi.org/10.3390/ma15093110

Muccillo R, Muccillo ENS, Kleitz M, Densification and enhancement of the grain boundary conductivity of gadolinium-doped barium cerate by ultra fast flash grain welding, J. Eur. Ceram. Soc., 32 (2012) 2311–2316. http://dx.doi.org/10.1016/j.jeurceramsoc.2012.01.032

Cologna M, Francis SCJ, Raj R, Field assisted and flash sintering of alumina and its relationship to conductivity and MgO-doping, J. Eur. Ceram. Soc., 31 (2011) 2827–2837. https://doi.org/10.1016/j.jeurceramsoc.2011.07.004

Karakuscu A, Cologna M, Yarotski D, Won J, et al., Defect structure of flash sintered strontium titanate, J. Am. Ceram. Soc., 95 (2012) 2531–2536. https://doi.org/10.1111/j.1551-2916.2012.05240.x

Zapata-Solvas E, Bonilla S, Wilshaw PR, Todd RI, Preliminary investigation of flash sintering of SiC, J. Eur. Ceram. Soc., 33 (2013) 2811–2816. https://doi.org/10.1016/j.jeurceramsoc.2013.04.023

Muccillo R, Kleitz M, Muccillo ENS, Flash grain welding in yttria stabilized zirconia, J. Eur. Ceram. Soc., 31(8) (2011) 1517–1521. https://doi.org/10.1016/j.jeurceramsoc.2011.02.030

Ahamer CM, Opitz AK, Rupp GM, Fleig J, Revisiting the temperature dependent ionic conductivity of yttria stabilized zirconia (YSZ), J. Electrochem. Soc., 164 (2017) F790–F803. http://dx.doi.org/10.1149/2.0641707jes

Francis JSC, Cologna M, Raj R, Particle size effects in flash sintering, J. Eur. Ceram. Soc., 32 (2012) 3129–3136. http://dx.doi.org/10.1016/j.jeurceramsoc.2012.04.028

Bhandari S, Mishra TP, Guillon O, Yadav D, et al., Accessing the role of Joule heating on densification during flash sintering of YSZ, Scripta Materialia, 211 (2022) 114508. https://doi.org/10.1016/j.scriptamat.2022.114508

Hao X, Liu Y, Wang Z, Qiao J, et al., A novel sintering method to obtain fully dense gadolinia doped ceria by applying a direct current, J. Power Sources, 210 (2012) 86–91. https://doi.org/10.1016/j.jpowsour.2012.03.006

Soleimany M, Paydar M, Investigation on flash sintering of BaZr0.1Ce0.7Y0.2O3-d compound; using nickel wire as electrode material, Ceram. Int., 46 (2020) 2128–2138. http://dx.doi.org/10.1016/j.ceramint.2019.09.196

Grasso S, Sakka Y, Rendtorff N, Hu CF, et al., Modeling of the temperature distribution of flash sintered zirconia, J. Ceram. Soc. Jap., 119 (2011) 144-146. https://doi.org/10.2109/jcersj2.119.144

Wang S, Mishra TP, Deng Y, Kaletsch A, et al., Experimental and numerical studies of densification and grain growth of 8YSZ during flash sintering. Adv. Eng. Mater., 25 (2023) 2201744. https://doi.org/10.1002/adem.202201744

Rybakov KI, Olevsky EA, Krikun EV, Microwave sintering: fundamentals and modeling, J. Am. Ceram. Soc., 96 (2013) 1003–1020. https://doi.org/10.1111/jace.12278

Yu S, Gu Yu, Bi L, Microwave heating technology for electrolytes of solid oxide fuel cells, Russ. Chem. Rev., 91(11) (2022) RCR5061. https://doi.org/10.57634/RCR5061

Ćurković L, Veseli R, Gabelica I, Žmak I, et al., A review of microwave-assisted sintering technique. Transactions of Famena XLV-1, (2021). https://doi.org/10.21278/TOF.451021220

Leriche A, Hampshire S, Cambier F. Sintering of ceramics. Reference module in materials science and materials engineering. Elsevier, 2017, https://doi.org/10.1016/B978-0-12-803581-8.10288-7

Vanetsev AS, Orlov AV, Tretyakov YD, High density BaCeO3 ceramics sintered using microwave irradiation, MRS Online Proceedings Library, 906 (2005) 104. https://doi.org/10.1557/PROC-0906-HH01-04

Amiri T, Etsell TH, Sarkar P, Direct microwave sintering of poorly coupled ceramics in electrochemical devices, J. Electrochem. Sci. Technol., 13(3) 2022 390–397. https://doi.org/10.33961/jecst.2022.00290

Hussain A, Hassan M, Song R-H, Khan MZ, et. al., Ultra-fast route to fabricate large-area anode-supported solid oxide fuel cell via microwave-assisted sintering, Ceram. Int., 49(18) 2023 30452–30460. https://doi.org/10.1016/j.ceramint.2023.06.309

Zhong Z, Xu X, Zhang Z, Li J, et al., Int. J. Hydrogen En., 47(60) (2022) 25367–25377. https://doi.org/10.1016/j.ijhydene.2022.05.292

DOI: https://doi.org/10.15826/elmattech.2024.3.040

Copyright (c) 2024 Liliya A. Dunyushkina

This work is licensed under a Creative Commons Attribution 4.0 International License.