Influence of alloying parameters on the structure and properties of AK-6 aluminium alloy

Abstract

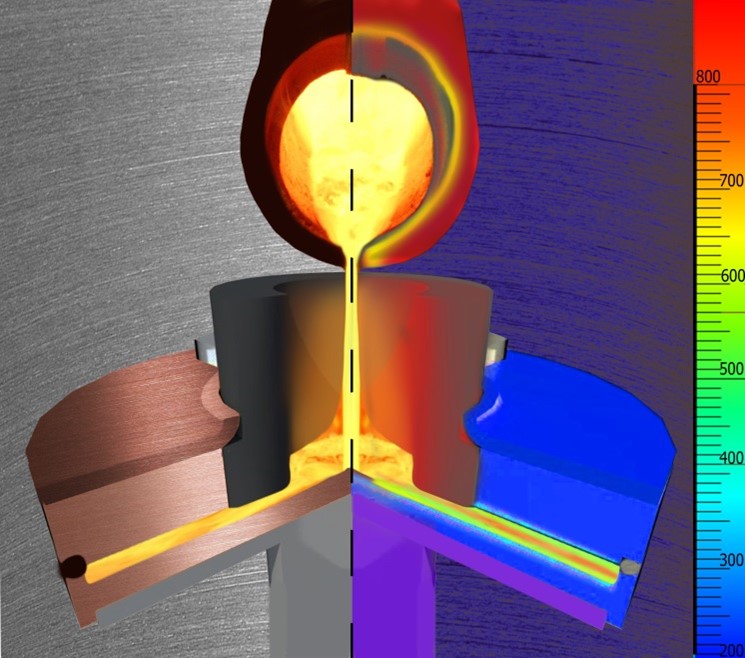

This work is devoted to the study of the effect of zirconium addition and crystallization rate on the structure and properties of industrial aluminium alloys. Experimental alloying of the AK6 alloy was performed. The required amount of Al-Zr-10 alloy (10 wt. % Zr) was added at a temperature of 900 °C until the zirconium content in the target alloy reached 0.1; 0.3; 0.5 wt. %. According to the results of scanning electron microscopy and X-ray diffraction analysis, the main proportion of zirconium in the initial alloy was represented by intermetallic compounds of predominantly Al3Zr composition and sizes from 5 to 50 μm. Values of microhardness measured after direct alloying of high-purity aluminum with zirconium by the electrolysis of oxide-fluoride melts demonstrate that at a zirconium content of 0.4 wt. %, the microhardness of the alloy increases by 1.5 times and continues to grow as the zirconium content increases. Based on the results of structural analysis, it was found that the average grain size of the aluminium alloy decreased by 4–5 times even at a Zr content of 0.1 wt. %. When studying the properties of the obtained samples, it was found that the addition of zirconium to the AK6 alloy does not affect its hardness, in contrast to high-purity aluminium, which is presumably due to the more pronounced influence of other components and the absence of an additive effect of zirconium on the alloy hardness. Accelerated cooling of the alloy to 103 K/s without zirconium additives has a similar effect of grain reduction, and also increases the microhardness of the alloy by 10 HB according to Brinell. A study of the combined effect of zirconium addition and accelerated cooling shows the additive effect of grinding by more than 25 times, while individual grains do not exceed 5 microns in size. The absence of intermetallic compounds in the obtained samples of the AK6 alloy after modification with the Al-Zr alloy indicates that the phase composition of the initial Al-Zr alloy does not affect the properties of the target alloys.

Keywords

Full Text:

PDFReferences

Filatov AA, Suzdaltsev AV, Zaikov YuP, Modifying Ability of an Al–Zr Master Alloy, Rus. Met. (Metally), 2021 (2021) 1036–1039. https://doi.org/10.1134/S0036029521080073

Kononov A, Polyakov E, High-temperature electrochemical synthesis and properties of intermetallic compounds of the Ni-Sc system Part 1. Electrochemical behaviour of Sc(III) in chloride-fluoride melts, Journal of Alloys and Compounds, 239(2) (1996) 103–106 https://doi.org/10.1016/0925-8388(96)02209-8

Yuekun G, Jie L, Shengxiang Q, Yida D, et al., Electrodeposition of alloys and compounds from high-temperature molten salts, J. of Alloys and Comp., 690 (2017) 228–238. https://doi.org/10.1016/j.jallcom.2016.08.104

Ehsan G, Rahim Y, Keivan A, Touradj E, Production of Al-SiC-TiC hybrid composites using pure and 1056 aluminum powders prepared through microwave and conventional heating methods, J. of Alloys and Comp., 690 (2017) 512–518. https://doi.org/10.1016/j.jallcom.2016.08.145

Rajagopalan PK, Sharma IG, Krishnan TS, Production of Al–Zr master alloy starting from ZrO2, J. of Alloys and Comp., 285(1–2) (1999) 212–215. https://doi.org/10.1016/S0925-8388(98)00754-3

Emilia K, Vladimir D, Jan H, Advanced technology for Al-Zr alloy synthesis: Electrochemical investigation of suitable low-melting electrolytes, J. of Alloys and Comp., 738 (2018) 151–157. https://doi.org/10.1016/j.jallcom.2017.12.136

Ravi KK, Pridhar T, Sree Balaji VS, Mechanical properties and characterization of zirconium oxide (ZrO2) and coconut shell ash (CSA) reinforced aluminium (Al 6082) matrix hybrid composite, J. of Alloys and Comp., 765 (2018) 171–179. https://doi.org/10.1016/j.jallcom.2018.06.177

Suzdaltsev AV, Pershin PS, Filatov AA, Nikolaev AYu, et al., Review-Synthesis of Aluminum Master Alloys in Oxide-Fluoride Melts: A Review, JES, 167(10) (2020) 102503. https://doi.org/10.1149/1945-7111/ab9879

Filatov AA, Suzdaltsev AV, Zaikov YuP, Production of Al-Zr Master Alloy by Electrolysis of the KF-NaF-AlF3-ZrO2 Melt: Modifying Ability of the Master Alloy, MMTB, 52(6) (2021) 4206–4214. https://doi.org/10.1007/s11663-021-02340-1

Filatov AA, Pershin PS, Suzdaltsev AV, Nikolaev AYu, et al., Synthesis of Al-Zr Master Alloys via the Electrolysis of KF-NaF-AlF3-ZrO2 Melts, JES, 165(2) (2018) E28. https://doi.org/10.1149/2.0571802JES

Suzdaltsev AV, Filatov AA, Nikolaev AYu, Pankratov AA, et al., Extraction of Scandium and Zirconium from their oxides during the electrolysis of oxide–fluoride melts, Rus. Met. (Metally), 2018(2) (2018) 133–138. https://doi.org/10.1134/S0036029518020180

Pershin PS, Kataev AA, Filatov AA, Suzdaltsev AV, et al., Synthesis of Al-Zr Alloys Via ZrO2 Aluminum-Thermal Reduction in KF-AlF3-Based Melts, MMTB, 48 (2017) 1962–1969. https://doi.org/10.1007/s11663-017-0976-y

Tkacheva OYu, Brodova IG, Arkhipov PA, Zaikov YuP, Effect of crystallization conditions on structure and modifying ability of Al–Sc alloys, Izvestiya. Non-Ferrous Metallurgy, 6 (2016) 55–64. (In Russian). https://doi.org/10.17073/0021-3438-2016-6-55-64

Xiaojing X, Xiaopeng J, Zheng L, Bin Z, et al., Influence of large amount Zn on mechanical properties and corrosion resistance of 5083 hot rolled aluminum alloy, App. Phys. A, 126 (2020) 713. https://doi.org/10.1007/s00339-020-03908-5

Xiaojing X, Xiaopeng J, Zheng L, Bin Z, et al, Microstructure and properties of a new Al–Cu–Mg–Zn–Zr–Ti heat resistant aluminum alloy, Mater. Res. Express, 6(12) (2019) 1265h8. https://doi.org/10.1088/2053-1591/ab6c03

Wang F, Eskin DG, Khvan AV, Starodub KF, et al., On the occurrence of a eutectic-type structure in solidification of Al-Zr alloys, Scripta Mater., 133 (2017) 75–78. https://doi.org/10.1016/j.scriptamat.2017.02.027

Chikova OA, Boris VO, Pavel LR, The Study of the Dissolution AlZr2 Ligatures in the Liquid Alloy AlMg6Mn1, Mater. Sci. Forum, 870 (2016) 243–247. https://doi.org/10.4028/www.scientific.net/MSF.870.243

Krokhin AY, Mann VK, Ryabov DK, Babitskiy NA, Effect of treatment parameters on structure, mechanical and corrosion properties of Al-Mg-Sc alloy forgings with reduced concentration of scandium, The Minerals, Metals and Materials Series Part F4, (2018) 1573–1580. https://doi.org/10.1007/978-3-319-72284-9_205

Kang W, Li HY, Zhao SX, Han Y, et al., Effects of homogenization treatments on the microstructure evolution, microhardness and electrical conductivity of dilute Al-Sc-Zr-Er alloys, J. of Alloys and Comp., 704 (2017) 683–692. https://doi.org/10.1016/j.jallcom.2017.02.043

Elagin VI, Samarina MV, Zakharov VV, Ways for improving the properties of semiproducts from V96Ts-3-type high-strength aluminum alloys of the Al – Zn – Mg – Cu system, Met. Sci. Heat Treat., 51 (2009) 515–521. https://doi.org/10.1007/s11041-010-9204-y

DOI: https://doi.org/10.15826/elmattech.2024.3.034

Copyright (c) 2024 Aleksandr A. Filatov

This work is licensed under a Creative Commons Attribution 4.0 International License.